Inline Packaging

Food Packaging and Bottling Industry Experts

Find the perfect machine for your business

Custom or Predesigned

Start Your Project Today

→

Get Technical Support

→

Pride in our product- and our nation

Very few, if any, of our competitors can actually claim to make the equipment they sell. Most of them either directly import their machinery from China and sell it just as it is, or import it from China into a warehouse, where they make a few small tweaks to it and then try to sell it with the claim that it’s “made in America.” At In-Line Packaging, you can rest assured- every piece of equipment we sell is completely and wholly American-made.

On top of our pride in our country, we carry a great deal of pride in the equipment we produce. That’s why we offer a one-year warranty on all of our machines. That’s how confident we are in our ability to produce machines that work well, and that work efficiently.

Another benefit to using our product is that you’ll also receive expert support from the same people who designed and assembled your machinery. Nothing can beat the convenience of troubleshooting with the very individuals who put together your equipment. If you need a solution to your bottling or packaging process, we are the place to find it- and fix it.

NEED REPLACEMENT PARTS?

ABOUT US

We started In-Line Labeling over a quarter of a century ago. In our early days, we were a relatively simple operation that provided support and rebuilt cold-glue labeling machines. Since then, though, we’ve grown exponentially.

Today, In-Line Packaging is proud to design and launch our own machines and systems that provide a wide range of services. We’ve produced and sold thousands of machines- and that number continues to grow with each passing day. We attribute our success to two things: one, In-Line Packaging equipment is 100% made in America, and two, our product speaks for itself.

In-line Equipment

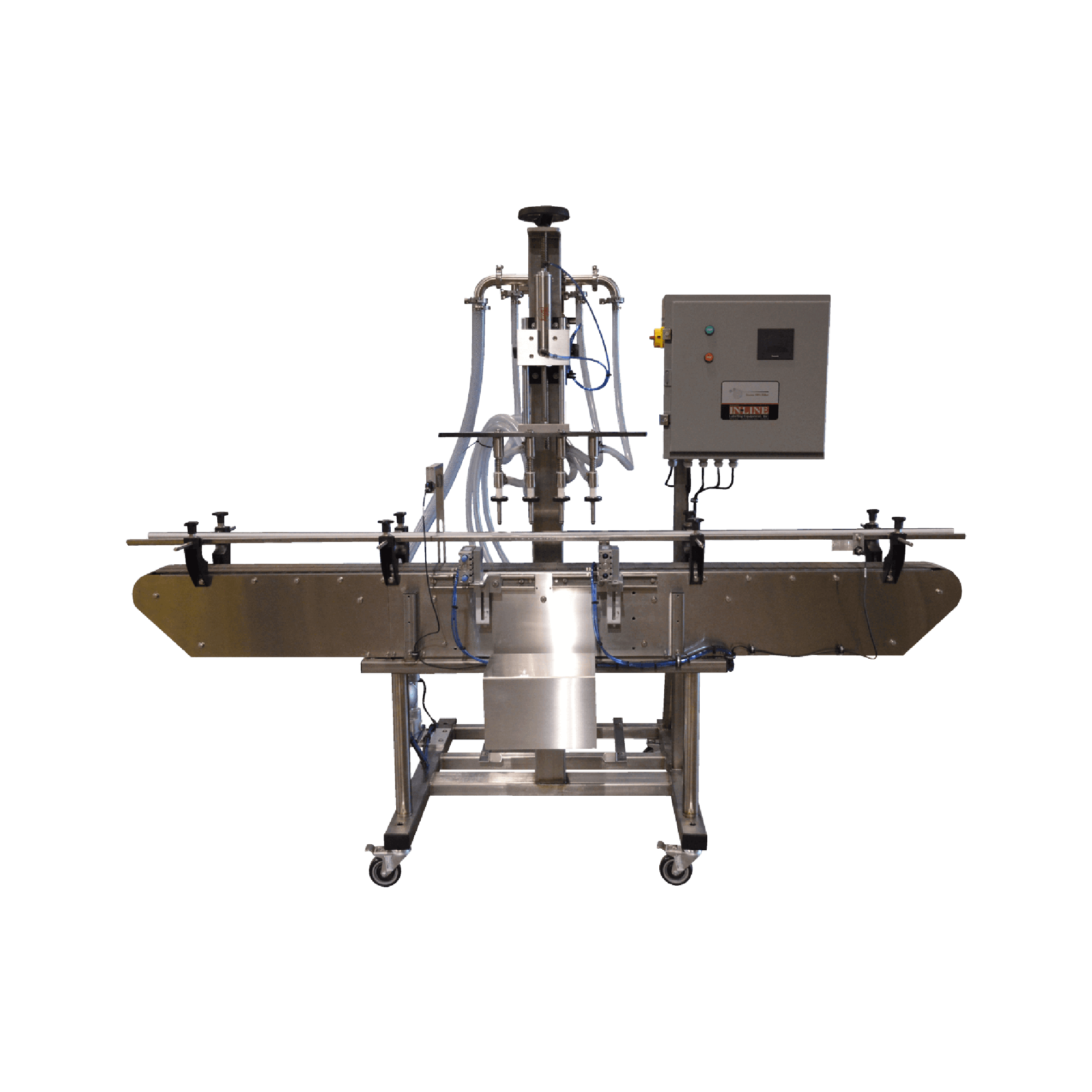

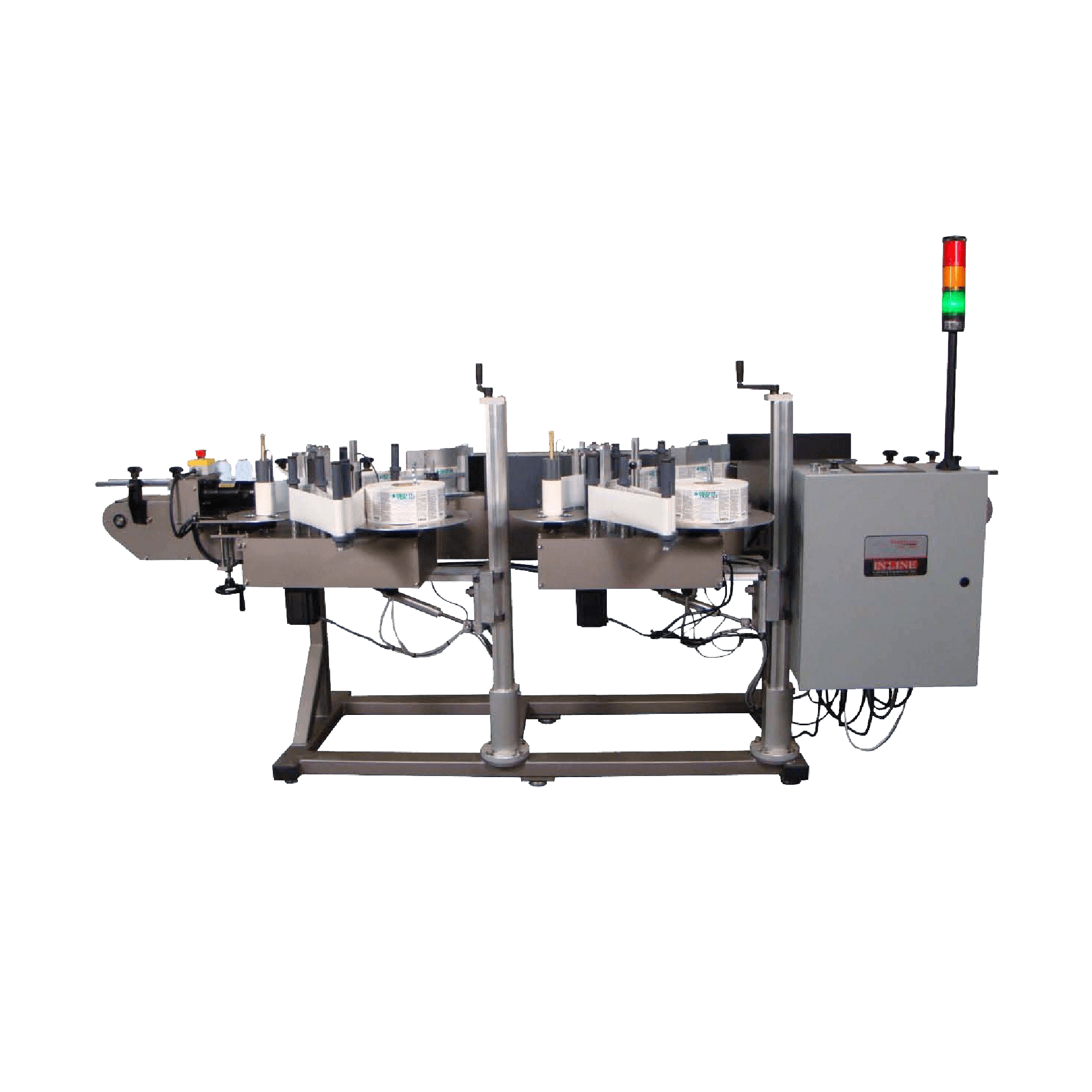

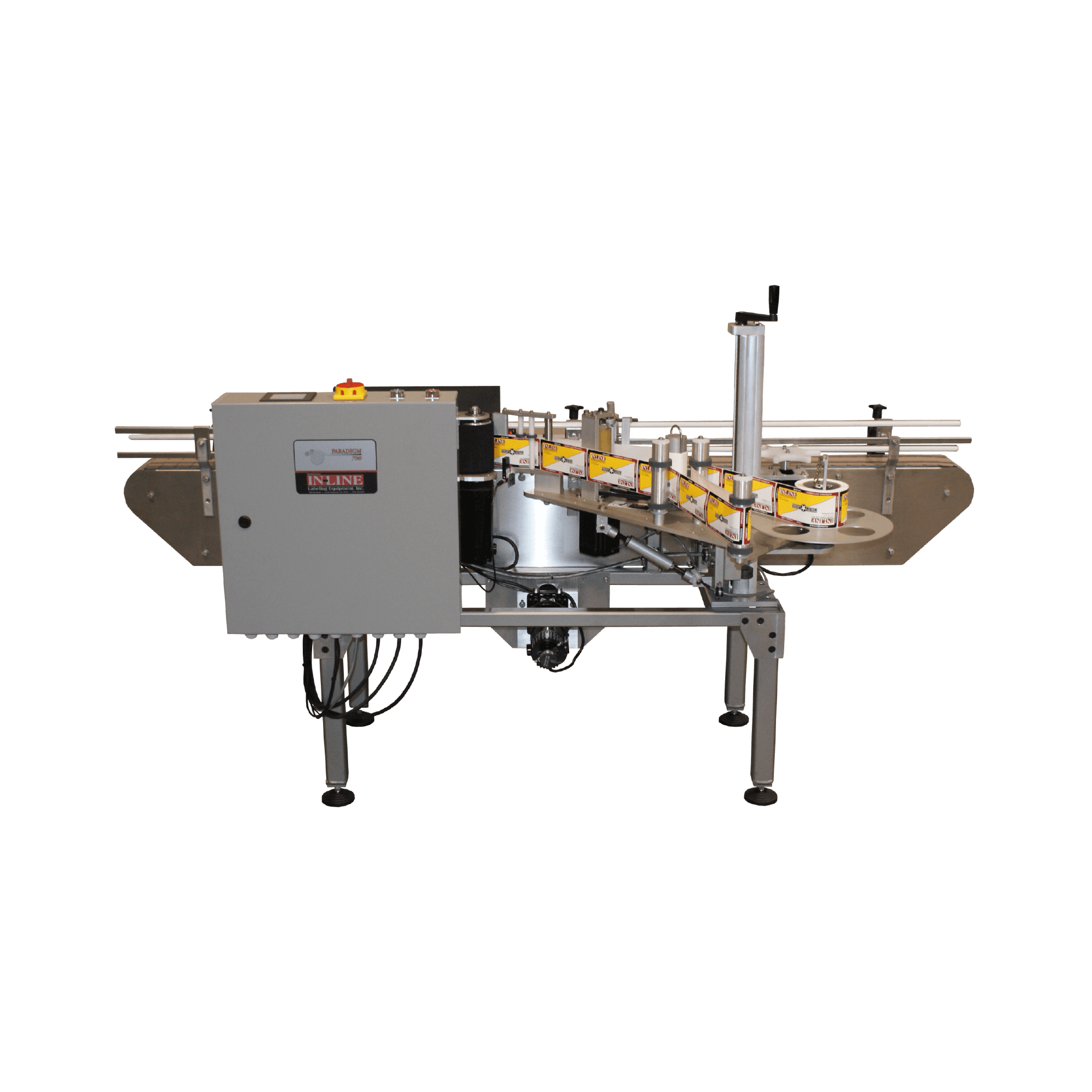

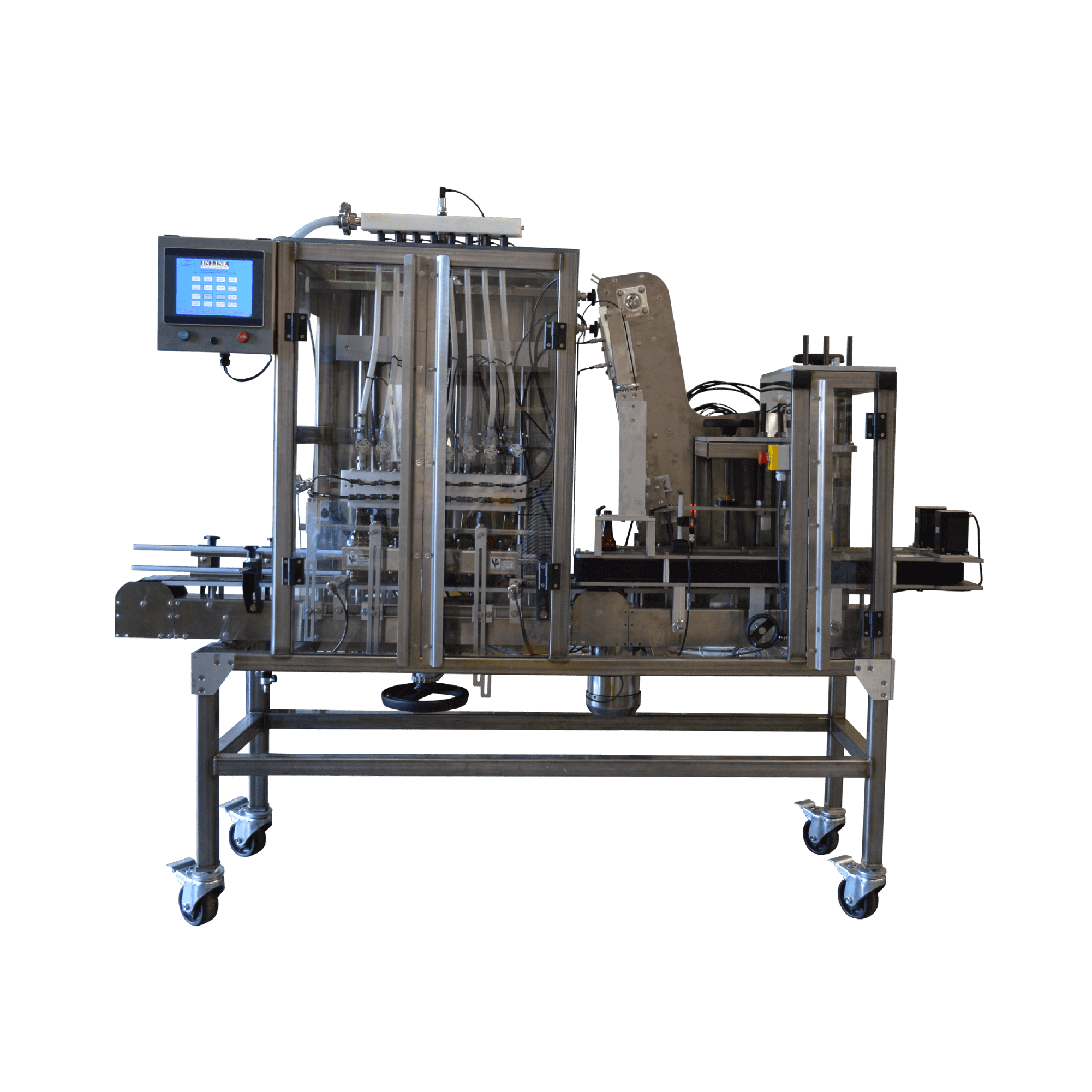

At In-Line Packaging, we’re proud to produce all different kinds of equipment that will help you produce the best food and beverages you can. From brewery equipment and distillery equipment to food packaging equipment, bottle fillers, and labeling machinery, we’ve got you covered. Don’t see what you’re looking for? Have an idea for something outside the box that you’d like us to make? No problem; we make custom machinery for your custom business, too!

Distilleries

Learn More →

Food Packaging

Learn More →

Labeling

Learn More →

Fillers

Learn More →

Conveyance Equipment

Learn More →

the latest from Inline

Packaging Machinery Case Study: BHAWK

As an experienced packaging machinery manufacturer, we often receive a lots of requests on whether we can automate a certain container for new or current customers or not. Compared to our competitors, we have much more flexibility to build turnkey filling, capping,...

Tech Note Tip: Why can’t I jog my machines devices?

Why can't I jog my machines devices? Are you wondering why you can’t jog any of your devices when trying to find out the source of a problem or set up the machine? In today’s tech tip, we are going to go over how to properly jog devices and why we have designed that...

Packaging Machinery Case Study: A Distillery and Brand Owner Team Up to Fill Both of Their Needs.

Distilleries that are implementing a growth strategy for their distillation, diversity of spirits, or distribution are moving into automation in each area. Craft Distilleries are looking for efficient ways to get their premium spirits into the bottle, decorated, and...

We Just Launched our New Shrink Capsule Applicator!

What Are they Up to This Time??? Introducing our PVC Shrink Capsule Applicator There is always something new cooking at In-Line Packaging Systems Inc. Whether it’s a new custom build, out of the box filling, or labeling machine, we're always up to something. Lately...

Get In Touch

Do you have a question or a concern about one of our products? Are you interested in purchasing one of our food packaging or bottling machines, but would like more specific information first? Do you simply have a question regarding how our service works? We’re here to provide answers to those questions and arm you with all the knowledge you could possibly want about what we do and how we do it.

7282 Spa Rd

North Charleston, SC 29418

Email: info@inlinepack.com

Phone: (843) 569-2530

Fax: (843) 576-0798

Visit the InLine Packaging Team at an Upcoming Event

- American Distillers Institute Las Vegas 8/23-24

- Pack Expo Las Vegas 9/11-13

- Process Expo- Chicago 10/23-25