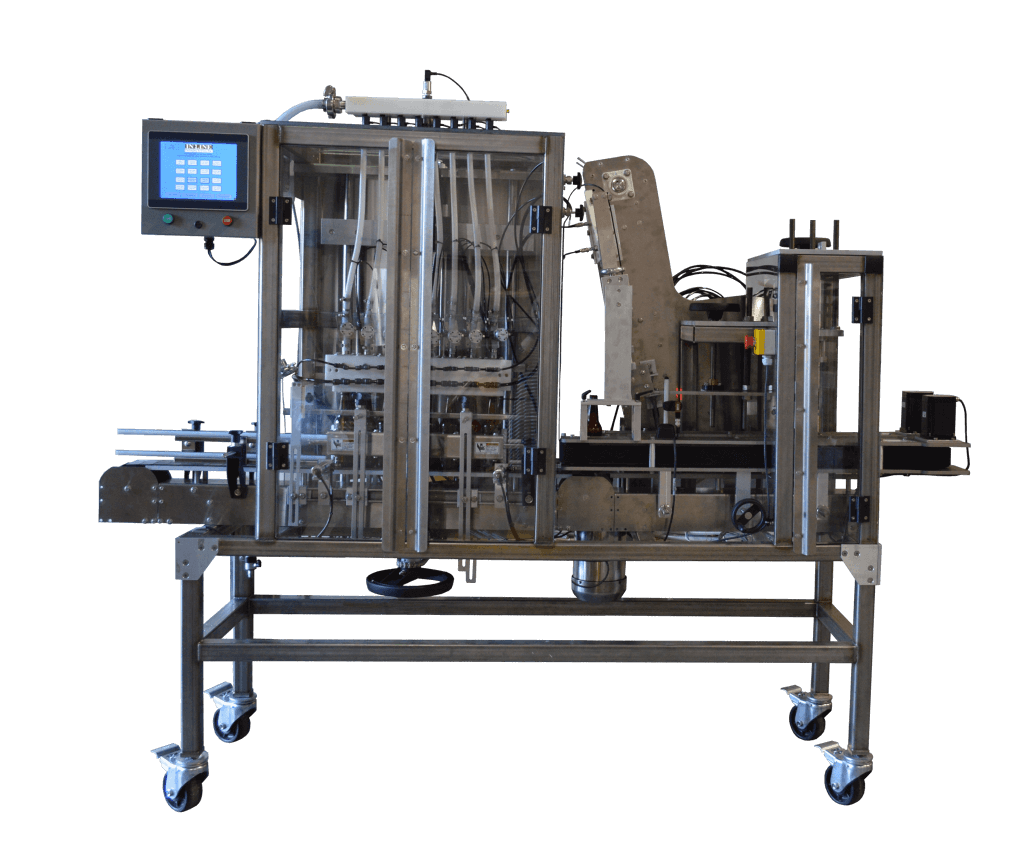

The Micro Carbonated Filler can fill 12 oz bottles up to 24 bpm with the 4 Head, up to 30 bpm with the 6 Head, and up to 36 bpm on the 8 Head, depending on beer pressure and temperature. Any bottle size from 8 oz up to 750 ml can be handled in the same machine with manual adjustments and minimal change parts.

Container handling is fully automatic—there is no manual loading or unloading of bottles. When ready, bottles are shuttled over and stopped under the filling heads. Our filling heads use genuine liquid pinch valves to control beer flow. Flow meters on each head allow for fine adjustments of the fill height. When complete, the bottles are transferred using hugger belts to the crowning conveyor, where a crown is crimped on the bottle. After completion, bottles exit onto an accumulation table for pack off.

*Option to substitute Crowner with Screw Capper or Corker.

Our Micro Carbonated Filler is versatile to meet your individual brewery operation. With minimal changes, you can quickly alter your system and get your beverage into customers’ hands quicker. With our genuine liquid pinch valves, there’s no overflow or waste, saving you money and cleanup time. Quickly change between 8oz up to 750ml bottles.

Contact us today, and we’ll get you started on a tailored brewery solution for your business, enhancing your overall operation in the labeling machinery landscape. Our commitment to quality and innovation ensures that you receive a top-tier product and the support you need to thrive in a competitive market. With In-Line as your partner, you can focus on what you do best: brewing exceptional beverages and delivering them to your customers reliably and efficiently.