Ska Fabricating specializes in the design and integration of Date Inline Coding Systems. Date coding cans has become a hot topic in the micro brewing industry. Ensuring that customers are buying fresh product should be a primary concern for brewers and date coding your product is an important step.

After many requests to come up with a good date coding solution for our customers Ska Fabricating came up with an alternative to date coding in your rinse cage. While date coding in the rinse cage gives marginal results, there is a need to have a better system out there.

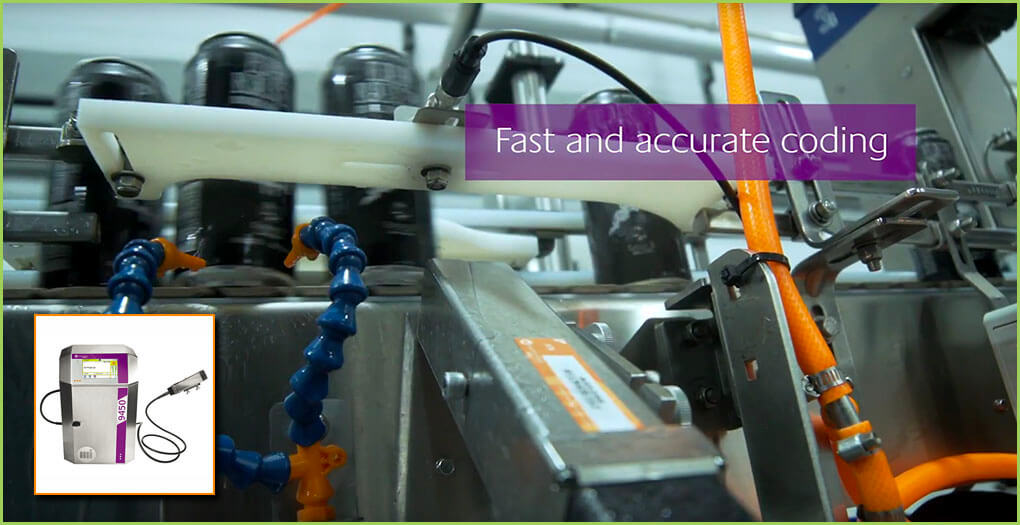

Ska Fabricating has developed a Quality Control Conveyor system to implement can drying, date coding and low fill checking all onto one conveyor. Our modular system is easily implemented between your filler/seamer and your method of six packing. This is a bolt on solution that is easily implementable. We make a custom bracket for the Markem Imaje print head so it integrates effortlessly into the line.

Markem-Imaje 9450 Date Code Printer

If improving the efficiency of your production process is one of your priorities, the new 9450 coder was engineered for you. The new Markem-Imaje 9450 is designed to be fully available, keep up with your line speed and secure each of your products with the right code!

Your benefits

• Maximize your production performance

• Up to 99.9% availability rate

• Up to 20% reduction in consumable use and energy consumption (no need for plant air) and minimizes your waste expenses

• Wash it down with pressured water and industrial detergent and make sure your hygiene standards are met (IP56 standard, IP66 optional)

• Automatic cleaning system will ensure jet stability remains perfect when restarting

• Smart consumable system. No set-up required

• Promotional coding and serialization functions to support your marketing initiatives

• Ink references with a high level of adhesion, contrast and color as well as anti-diversion solutions and environmentally friendly inks

• Easy running cost tracking via smart monitoring system

• Code integrity is automatically checked via the new embedded Mark & Read vision system

Print Features

• Mono-jet printhead

• G head (printing resolution: 71 dpi)

• M head (printing resolution: 115 dpi)

• Up to 5 lines of print

• Print speed: up to 6.6 m/s

• Font height from 5 to 32 dots

• Character height: from 1.2 to 11.2 mm

Operation

Message library (up to 1000 messages)

• International operator/machine interface with a wide choice of languages

• WYSIWYG 7-inch wide touch screen: realtime display of remaining print capacity expressed in hours and number of messages; integrated assistance and alert system; simplified message printing and management; creation of user profiles; tracking of consumption and printer availability

• USB and SD ports

• Jet speed Control guarantees marking quality

• Automatic selection of fonts, depending on print speed and printhead / object distance

• Broad range of inks: multi-use, high performance; alcohol-based, ketone-free and Mek-free inks

• Sealed 0.8-liter cartridges with foolproo ng system

• Quick connect/disconnect of accessories (photocell, alarm and encoder)

• Parent/child connectivity

• Specifc date management (rounding date function)

date machine operation

Exhibit A Brewing with Matthew Steinberg

https://www.youtube.com/embed/zPhyI8HFP5A

Markem-Imaje 9450 Date Coder

https://www.youtube.com/embed/WDAONtvQekc