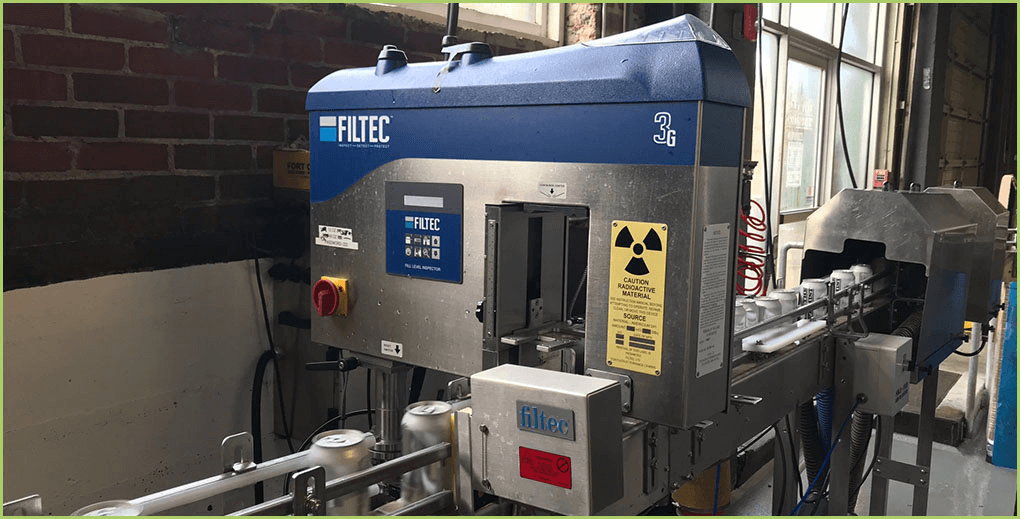

The Filtec 3 – Full container inspection detects over and under filled containers and capping defects. It inspects for over filling and under filling cans or bottles, and if the can end or bottle lid are fitted correctly. The Filtec 3 inspection system detects these issues as they arise on the filling line, as well as identifying bulged cans, high or low foam levels, glass bottle breakages, containers falling over on the line, and where applicable, missing foil seals.

The system is capable of handling filling line speeds – it runs at up to 2,400 cans a minute or 1,400 bottles a minute – and collects data as it goes, keeping count of the total number of containers analyzed and the total number of rejected parts. It also offers real-time continuous statistical analysis of the data, and uses sampling to monitor the performance of filler valves and the capping and closing heads, enabling the system to identify if a fault within an individual station is causing rejects.

System Highlights:

- Small Footprint

- Option of Gamma Ray, X-Ray Systems

- No precise bottle pitch or spacing requirements

- Total and individual throughput and reject counters

- Advanced diagnostics

- Encoder-based tracking

- PLC interface

Additional Feature Options:

- Vent tube detection

- DUD detection

- Reject verification

- Label detection

- Touch screen user interface

Systems:

- Continuous monitoring and statistical analysis of line operations

- Sampling of filler valves and closer/capper heads at high production speeds

- Isolates and evaluates performance of individual filler valves and closer/capper heads