Fillers

One of the many reasons that you’re able to sit back in your recliner chair and enjoy that perfect beverage is because of the process of filling that bottle with that beverage. Naturally, if something were to go wrong during that process, you wouldn’t be able to enjoy that beverage. With In-Line Packaging’s top-of-the-line filling equipment, you can rest assured knowing that your beverage of choice was assembled with the utmost care and precision.

Versatile filling Machinery

During the filling stage of production, accuracy is everything, with no margin for error. To prevent waste and unpredictable results, go with the precision and efficiency of In-Line beverage filler machines! From beginning to end, we provide the solutions for your assembly line. With our variety of machines available, you will find a system that works – from our carbonated beverage filler to our overflow filler and manual beer bottle filler. We consider the whole system when we design our machines – from the entire production line to the smallest detail like the overflow filling nozzle – so they work seamlessly, saving you time, resources, and headache. You have enough to do. Get back to business and product development and let In-Line tackle your production and packaging challenges. It’s what we do.

You need speed and efficiency when it comes to preparing your product for shipping. You can find that with In-Line! Plus, you’ll have the In-Line expertise and service behind your machinery, so you can contact us for help anytime. Our one-year guarantee means you can rely on us to troubleshoot any issues and help with improvements to your system. We have been designing filler machines, labeling machinery, and packaging systems since 1997 and our passion is to provide sensible solutions with precision and longevity.

Find the Filling Machinery to Meet Your Needs

Our customers can tell the difference, and you will too! Choose a local company that uses American labor and assembly. Unlike the large foreign companies, you can rely on In-Line to provide you the personal service of a local company with the expertise of experienced technicians. After all, ingenuity, hard work, reliability, and experience – all marks of a great, American company! Count on us and we will get your systems going fast and running smoothly for years to come.

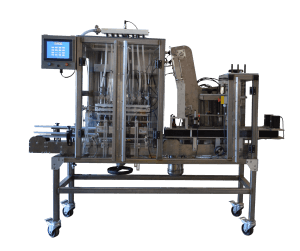

- Mini Bottle Filler & Capper

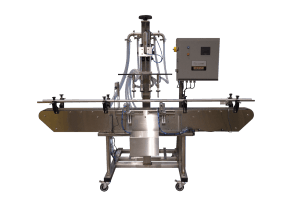

- Pressure Overflow Filler

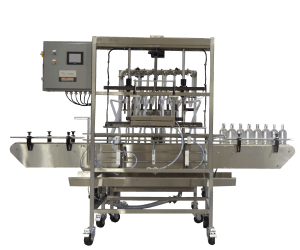

- 8-Head Gravity Overflow Filler

- Economy Filler

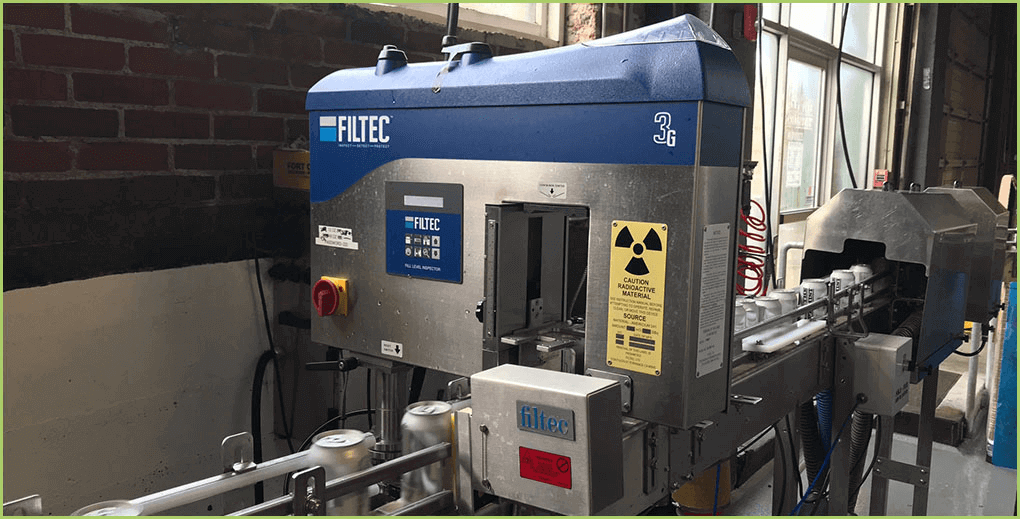

- Full Container Detection

- Micro Carbonated Filler

- Date Inline Coding Systems

- Can Rinse and Drying System

- PD Pump/Piston Filler

The In-Line mini bottle filler and cap tightener system utilize advanced technology and people-friendly controls to provide a simple and cost-effective method for container handling, filling, and cap torqueing.

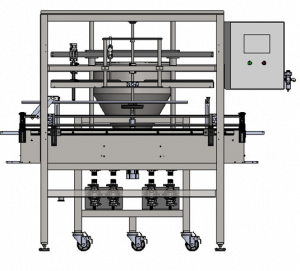

Based on a fill-to-level principle, the Model OF Pressure Overflow Filler delivers a quantity of flowable liquid into the container until it reaches an adjustable fill height.

Based on a fill-to-level principle, the Model GO-8 Gravity Overflow Filler delivers a quantity of flowable liquid into the container until it reaches an adjustable fill height.

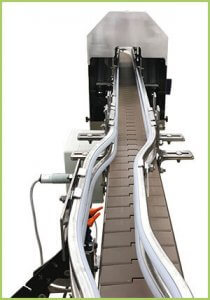

Containers enter the filling area in groups. When the last container in the group passes the mounted counting sensor, a pneumatic gate will engage and prevent other containers from interfering in the filling process.

Incoming round containers are spaced using a single-powered feed screw. Non-round containers require dual-feed screws. The conveyor is driven by a variable-speed motor.

The Filtec 3 – Full container inspection detects over and underfilled containers and capping defects. It inspects for overfilling and underfilling cans or bottles, and if the can end or bottle lid is fitted correctly.

Our new Micro carbonated beverage filler uses true pre-evac counter pressure technology to monitor bottle pressure and product pressure in controlling fills.

The Inline packaging system specializes in the design and integration of Date Inline Coding Systems. Date coding cans has become a hot topic in the microbrewing industry. Ensuring that customers are buying a fresh product should be a primary concern for brewers and date coding your product is an important step.

The Inline Packaging System Can Rinse and Drying System is a perfect addition to your canning line. The system uses Republic® air knives combined with our custom-designed can rinser and enclosures.

BE THE BEST, USE THE BEST

Think about it this way. You put a lot of hard work, time, and consideration into your product. Why not continue to ensure your attention to detail is the best it can be with flawlessly built equipment from In-Line Packaging? Find your brewery labelers, beer labelers, bottling line equipment, pressure-sensitive labelers, manual beer bottle filler, beer canning machinery, and more all from one trusted source- and support American labor at the same time.

We stand behind our products

Our wide array of machines can complete your labeling, filling, and packaging tasks seamlessly- as has been the case for a quarter of a century. Since 1997, we’ve been solving these needs for customers with our patented systems and developed a reputation for excellence in doing so.

To say we know the industry is an understatement. We know how to bottle like the back of our hand and we know how to get the job done quickly, efficiently, and at the highest level, you’ll ever find. That’s why we offer a one-year warranty on our machines. After delivery, we are available for support. The same people who designed and assembled your machines are available to answer your questions and troubleshoot issues. You’ll never be left in the cold with In-Line!

Get In Touch

Do you have a question or a concern about one of our products? Are you interested in purchasing one of our food packaging or bottling machines, but would like more specific information first? Do you simply have a question regarding how our service works? We’re here to provide answers to those questions and arm you with all the knowledge you could possibly want about what we do and how we do it.